|

|

Application Instructions

EZ-Hot/Cold Coating is a one-part, water based design with seven ceramics blended into a heavy bodied coating that can be used to block the loss of heat in areas up to

400F. degrees, and as an insulation system over existing and operating hot pipes, tanks, elbows and values.

EZ-Hot/Cold Coat can be applied to metal, concrete, masonry and wood. |

|

|

SURFACE PREPARATION

New construction metal, concrete, masonry, wood

Power wash surface (3,500 psi) to remove loose or flaking paint and rust, and to clean the surface of dirt, oil, tar, grease and film.

|

|

|

Surface must be completely dry if surface moisture persists, wipe down prior to application.

|

|

|

If existing coating surface is glossed, it must be sanded and roughed before application, no gloss. |

|

|

Previously coated metal, concrete, masonry, wood

Power wash surface (3,500 psi) with citrus cleaner to remove loose or flaking paint, and to clean the surface of dirt, oil, tar, grease and film. Chlor-Rid should also be used to remove salts.

|

|

|

NOTE: Once a container is opened, the product must be used or repackaged and sealed well in an unlined metal can. If left open, the product will harden in the container.

|

|

|

Wipe down with Acetone to remove any loose particles and to completely dry the surface.

Surface must be completely dry before applying the coating.

|

|

|

If existing coating surface is glossed, sanding or roughing the surface must be done before application no glossed surface.

|

|

|

NOTE: If pack rust, scale or bright glossy painted surfaces exist, they must be removed by grit blast, power tool or needle gun down to surface rust. Once removed, begin with step 1 (power wash).

|

|

|

POT LIFE

Two hours at 70F. degrees if container is left open. APPLICATION |

|

|

|

MIXING

EZ HOT/COLD does not need mixing it comes ready to be

applied

No water should be added to the EZ HOT/COLD Coating appearance

is like a thick whipped cream with no lumps if the coating has bee seating for a

long time, it may be needed to mix slightly with a paint mixing blade.

|

|

|

NOTE: See attached question and answers that will more clearly explain this mixing process. Pictures have also been added to clearly show the consistency required. |

|

|

APPLICATION

EZ-Hot/Cold Coat was designed to be applied by spray:

If application is by spray, the preferred machine is the Graco Texspray RTX 1500 or a hopper gun with air control.

Prime with RUSTVACCINE when cleaned rusted metal needs to

be insulated

|

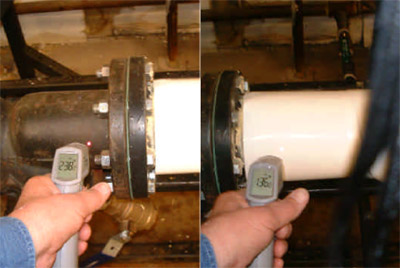

BEFORE

|

|

HOT APPLICATION

If application is directly to hot pipes (pipe surface temperature of 600F. degrees or less; if over 600F. degrees, contact the manufacturer for exact application instructions), first apply a thin coat fifty mils wet to act as a primer. Allow to set-up for five minutes, then apply additional coats as necessary to build to the required thickness. |

AFTER

|

|

AMBIENT APPLICATIONS

If application is directly on dry, non-operating pipes, since the surface is not hot and no problem of trapping steam bubbles in the coating film, the entire thickness desired can be applied in a single coat, according to hang allowance. Allow the final coat to set up for eight hours before heat is returned to the pipe. |

|

|

Two hours for each 200 mil coat applied; drying can be enhanced by introduction of heat. |

|

|

If exterior application is done, EZ-Hot/Cold Coat should be over coated with our top coating for UV protection and weathering. |

|

|

In all hot applications, EZ-Hot/Cold Coat is best applied in multiple coats build-up coats. |

|

|

For cold applications, never apply to pipes that are condensing or will be back in operation within thirty days when condensation is the problem. |

|

|

CURE TIME

Twelve hours to touch at 70F. degrees.

|

|

|

The overcoat window on dry, non operating pipes is eight hours at 70F. degrees or longer. |

|

|

Fully cures in thirty days with heat added to speed dry down. |

|

|

NOTE: The overcoat window on hot pipes is five minutes over hot surfaces. The overcoat window on dry, non-operating pipes is eight hours as an over coat for HCC. |

|

|

TEMPERATURE

Apply between 50F. and 100F. degrees.

|

|

|

Store between 40F. and 100F. degrees. |

|

|

CLEAN-UP OF EQUIPMENT

Spray equipment should be flushed and cleaned with soap and water.

|

|

|

MINIMUM SPREAD RATE:

|

|

|

IMPORTANT:

Do not take internally. Avoid contact with eyes. If solution does come in contact with eyes, flush immediately with water and contact a physician for medical attention. Avoid prolonged contact with skin or breathing of spray mist. For quickest removal from skin, wash with water before drying.

KEEP OUT OF REACH OF CHILDREN.

LIMITED WARRANTY:

Unless WALLPANEL Inc. provides a written warranty of fitness for a particular use,

WALLPANEL Inc. sole warranty is that the product, as supplied, will meet the current sales specifications and is specific only to return of product found to be defective upon opening of container within one year. Customer's exclusive remedy and

WALLPANEL Inc. sole liability for breach of warranty is limited to refund of the purchase price or replacement of any product shown to be other than as warranted and

WALLPANEL Inc. expressly disclaims

any liability for incidental or consequential damages.

|

- EZ-Hot/Cold Coat is designed to be applied directly over hot surfaces up to

400F

- Uncomplicated efficiency and top insulation against extreme heat conditions

- Can be used as insulation for Cold temperatures

- On Heat exchangers, Cold or Hot Pipes, Boilers, Water Heaters, Vending Equipment

- On Autos Fire Walls, Heat / Cold isolation, Ships, Aircraft

- Over primed metal surfaces

|

* RUSTVACCINE is another exeptional coating from WALLPANEL

Inc.

|